Crystal Lake Storage Tank and Treatment Plant Updates

Winsted, Connecticut

Project Scope

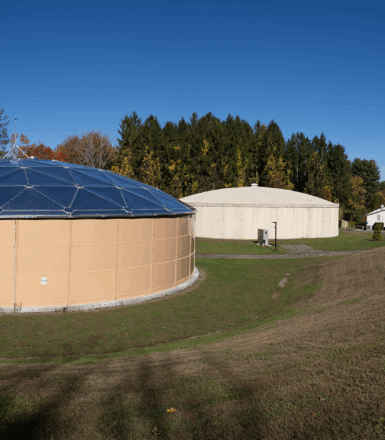

Haley Ward provided engineering, environmental, and construction administration services for the Crystal Lake Storage Tank and Treatment Plant Updates in Winsted, Connecticut. This project involved the design of a new 691,000-gallon glass-fused-to-steel potable water storage tank to provide system redundancy and ensure continued water service while the existing, deteriorating concrete tank is taken offline for critical repairs. Once both tanks are in operation, the system will benefit from improved water circulation, fresher water quality, and enhanced storage capacity for both drinking water and fire protection.

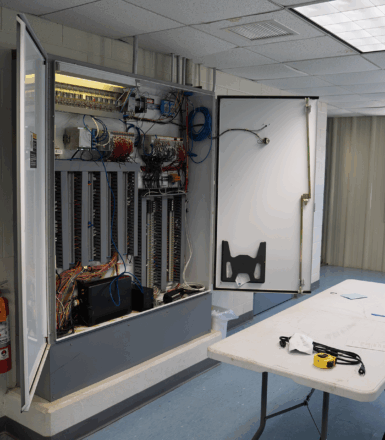

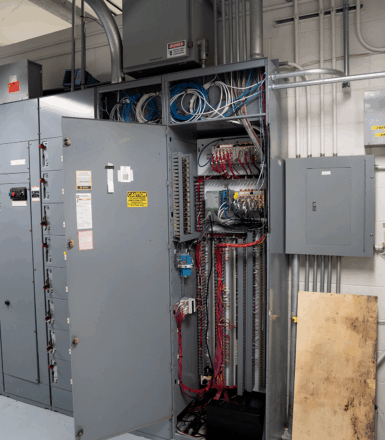

Haley Ward performed hydraulic modeling for the entire town to determine optimal system performance and storage needs. Project Manager Jim Ericson prepared chlorine contact time calculations to ensure regulatory compliance and proper disinfection balance—an essential factor for maintaining safe drinking water. The project also incorporated updated treatment plant components, modernized controls, and electrical design. U.S. Automation provided SCADA system design, and electrical design support was led by van Zelm Engineers.

This project faced challenges associated with the Drinking Water State Revolving Fund (DWSRF) program requirements, including compliance with the Buy American clause and the use of American Iron and Steel materials. The team also met Minority Business Enterprise and Women’s Business Enterprise (MBE/WBE) participation requirements through strategic subcontracting. Coordination with the State of Connecticut and the U.S. EPA was a key aspect of the project’s success, demonstrating Haley Ward’s expertise in navigating complex funding and compliance frameworks.

Design and surveying began in 2021, with construction completed in 2025.

Market

Services

- Hydraulic modeling and chlorine contact time analysis

- Land surveying

- Civil, structural, and electrical engineering design

- Permitting (planning, zoning, and wetlands)

- Coordination with DWSRF and U.S. EPA funding programs

- Construction administration and inspection (with MBE/WBE subcontract participation)

Project Data

| New 691,000-gallon storage tank | Added system redundancy, improved circulation, and increased potable water and fire protection capacity. |

| Hydraulic modeling & treatment plant upgrades | Town-wide modeling, chlorine contact time analysis, and modernized controls and electrical systems. |

| DWSRF-funded construction | Met Buy American and MBE/WBE requirements with coordinated state and EPA compliance. |